CERAMIC COMPONENTS for

Scientific Instrumentation…

As technology

advances, so too must the materials and processes that serve it. Ceramic components are

no exception. Ceramco manufactures world-class OEM ceramic parts, meeting the challenges

that technology presents with proven material formulations, on-going

engineering and its sophisticated,

yet cost efficient manufacturing process: near-net shaping.

As technology

advances, so too must the materials and processes that serve it. Ceramic components are

no exception. Ceramco manufactures world-class OEM ceramic parts, meeting the challenges

that technology presents with proven material formulations, on-going

engineering and its sophisticated,

yet cost efficient manufacturing process: near-net shaping.

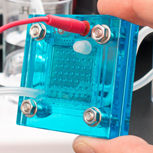

Electrically insulating, non-conductive, chemically stable and non-outgassing, OEM ceramic parts from Ceramco are used to make connectors, terminals, standoffs, and other insulators. Ceramic’s high dielectric strength keeps electricity contained and the electronic devices functioning. The performance of plastics and other organic materials, in similar applications, simply does not compare to the performance and long life of a Ceramco OEM ceramic part. Ceramco’s OEM ceramic parts deliver precision, dependability and performance each time the switch is thrown.

Within the field of scientific instrumentation, electronics (and related) Ceramco’s OEM components can be found in:

- Security devices – magnetic field, high voltage and contamination challenges

- Laboratory equipment – high temperature and contamination challenges

- Lasers – high temperature, surface finish and contamination challenges

Ceramic Components:

Helping to Keep Us Safe

Ceramic Components:

Helping to Keep Us Safe

Many events of the past decade have impacted the entire civilized world, but perhaps none more than terrorism and its ongoing threat. Governments are meeting this challenge not only with diligence, but with the use of highly sophisticated technology. As part of their search to detect volatile substances used in explosives, Homeland Security uses ion detection equipment which incorporates OEM ceramic parts from Ceramco. Ceramics are the right choice for this application because they are non-magnetic, do no conduct electricity and do not out-gas.

Ceramco OEM ceramic parts

are also found in passport scanners. Again… ceramics are chosen for their critical functionality and

reliable performance in the field. Mobile X-ray machines used to scan travelers, vehicles and their

cargo in search of harmful or destructive materials, also incorporate Ceramco OEM ceramic parts to

contain the extremely high voltages these devices require.

Ceramco OEM ceramic parts

are also found in passport scanners. Again… ceramics are chosen for their critical functionality and

reliable performance in the field. Mobile X-ray machines used to scan travelers, vehicles and their

cargo in search of harmful or destructive materials, also incorporate Ceramco OEM ceramic parts to

contain the extremely high voltages these devices require.

Ceramic Components: Helping Science Find Answers

When analysis is conducted on the atomic level, the slightest variation in accuracy of the laboratory equipment is unacceptable. Many laboratory tests involve the use of high temperatures. Also, maintaining sample purity is absolutely critical. The high purity of Ceramco’s aluminum oxide (Al2O3) effectively deals with the high temperatures and being chemically inert, it does not contaminate the sample. Ceramics are critical to these machines and to producing consistent and accurate results. Ceramco’s material formulations and the OEM ceramic parts manufactured from them, deliver both.

Laboratory measurement or

analysis utilizing Ceramco ceramic parts includes:

Thermogravimetric Analysis (TGA),

Differential Scanning Calorimetry (DSC),

Gas Chromatography-Mass Spectrometry (GCMS) and

Liquid Chromatography-Mass Spectrometry (LCMS). The high performance ceramic parts required in performing

these functions include:

Laboratory measurement or

analysis utilizing Ceramco ceramic parts includes:

Thermogravimetric Analysis (TGA),

Differential Scanning Calorimetry (DSC),

Gas Chromatography-Mass Spectrometry (GCMS) and

Liquid Chromatography-Mass Spectrometry (LCMS). The high performance ceramic parts required in performing

these functions include:

- Ceramic crucibles

- Ceramic sample pans

- Ceramic saggers

- Ceramic heating element cores

- Ceramic sample platforms

- Ceramic calibration weights

Ceramic Components: a

Specialized Focus

Ceramic Components: a

Specialized Focus

Whether produced using continuous wave or pulse mode, to output a beam of laser light requires a long list of materials and equipment, including: electronic devices, a dust free vacuum and highly polished, extremely reflective surfaces. Once the laser beam is generated, target areas routinely reach temperatures of 1000°C and higher.

Ceramics possess the inherent properties to effectively deal with all of these requirements and the environmental conditions that result. Ceramco’s OEM ceramic parts can be used in vacuum, easily withstand temperatures in excess of 1000°C, can be polished and are not subject to breakdown, introducing dust or other contaminates. Ceramco’s OEM ceramic parts are already helping laser manufacturers keep their focus on business.

People Making it Happen

Modern electronic devices and Ceramco share a similar trait. Both require what is within to be the very best. At Ceramco you will find only state of the art people meeting the challenges our customers present with precision, dependability and timely performance, just as they do the OEM ceramic parts we manufacture for them.

Ready to Make it Happen for You

Do you need a quotation on your print for an OEM ceramic part? Submit an RFQ now, or contact Ceramco. You'll be greeted by a courteous customer service specialist ready to provide immediate, personal assistance. Ceramco specializes in manufacturing OEM ceramic parts with complex geometries, matching the appropriate forming process to your order's specifications and quantity: