Materials…

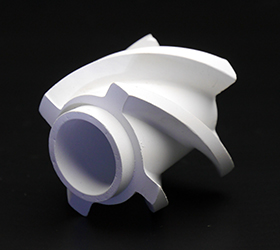

ZTA (Zirconia toughened Alumina)

ZTA, a combination of zirconium oxide and aluminum oxide, results in a component 20-30% stronger* than an alumina component of comparable size. ZTA provides the higher service temperature of alumina and the toughness of zirconia and contains no mixed oxides. Ceramco’s ZTA is 85% alumina (Al2O3), 15% zirconia (ZrO2). Our blend is named ZTA8.

ZTA, a combination of zirconium oxide and aluminum oxide, results in a component 20-30% stronger* than an alumina component of comparable size. ZTA provides the higher service temperature of alumina and the toughness of zirconia and contains no mixed oxides. Ceramco’s ZTA is 85% alumina (Al2O3), 15% zirconia (ZrO2). Our blend is named ZTA8.

When compared to zirconia, ZTA possesses:

- Similar density

- Superior hardness

- Greater bend strength

- Lower coefficient of thermal expansion

- Higher thermal conductivity

Compare Ceramco production formulation's material properties.

As a result of these desirable properties, an increasing number of Ceramco’s OEM ceramic component orders utilize ZTA, meeting the necessary design criteria in which zirconia was initially specified, at a lower price point.

OEM Market Candidates for Ceramco ZTA Include…

- Refractories

- Abrasives

- Instrumentation

- Lab ware

- Bio-medical devices

- Coatings

ZTA8 is the ideal material candidate to consider instead of alumina or zirconia. Although, the materials selection process is complex and important, Ceramco is an expert. Ceramco also offers numerous alumina and zirconia formulations, as well as user defined materials, satisfying almost any OEM ceramic parts requirement. Please review and compare our inventory of production formulations.

ZTA8 is the ideal material candidate to consider instead of alumina or zirconia. Although, the materials selection process is complex and important, Ceramco is an expert. Ceramco also offers numerous alumina and zirconia formulations, as well as user defined materials, satisfying almost any OEM ceramic parts requirement. Please review and compare our inventory of production formulations.

People Making it Happen

A highly trained and skilled group of people engineer, formulate and process Ceramco’s ZTA (and do so much more) for our customers. Ceramco engineers are experts in their knowledge of ZTA and in its application to the OEM ceramic parts we manufacture. We welcome questions or inquiries regarding specifics on Ceramco Ceramco ZTA and/or Ceramco ZTA applications.

Ready to Make it Happen for You

Do you need a quotation on your print for an OEM ceramic part? Submit an RFQ now, or contact Ceramco. You'll be greeted by a courteous customer service specialist ready to provide immediate, personal assistance. Ceramco specializes in manufacturing OEM ceramic parts with complex geometries, matching the appropriate forming process to your order's specifications and quantity:

Ceramco's Forming Process Methods

* No guarantee should be assumed or, is implied.