Summary of

Manufacturing Processes

for OEM Ceramic Components & Stock Ceramic Fasteners

Expertise, Value, Capability!

Many methods will yield a finished ceramic part. Knowing which method is the best choice requires

manufacturing expertise. Ceramco has the expertise and the in-house capability to match your

part to the best method.

Finished threads, undercuts, intersections and wall thicknesses as thin as 0.3 mm. All with little or no

grinding or machining. Rapid prototyping, short runs and quantities of 50,000 pieces (or more) annually,

all produced efficiently and economically in the USA, following

ISO 9001-2015 quality standards.

Support processing, including:

powder blending per cusomer specs,

full density machining,

glazing, coating and

assembly services also available.

Scalable and Vertically Integrated

Ceramco’s manufacturing processes are not optimized for any particular OEM

ceramic parts order quantity. Ceramco produces large and small quantities utilizing the same processes by

stepping-up the investment in tooling if necessary. Ceramco scales up easily when the customer is ready to move from

prototype or small quantity of their OEM ceramic part requiring no tooling, to a larger quantity or production

run. For more information on all of Ceramco's forming process methods, please refer to the images and

descriptions below.

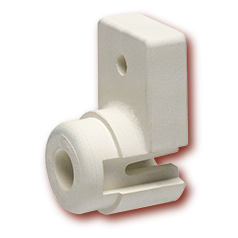

LPIM - Low Pressure Ceramic Injection Molding

Near-net shaped production

quantities* of 100 to 10,000 pieces annually utilizing tooling from type 6061 aluminum.

Providing both flexibility and value, LPIM tooling

can typically produce 10,000 ceramic parts before any maintenance is needed.

Learn more…

HPIM - High Pressure Ceramic Injection Molding

Near-net shaped production

quantities* of 10,000 pieces or more annually utilizing tool

steel as the material of choice to satisfy the increased volume requirements yet maintain the

precision on critical OEM ceramic parts features.

Learn more…

MicroPIM - High Pressure Ceramic Injection Molding Parts ≥ 0.05 Grams

MicroPIM is another high-volume, near-net

shaping production method virtually the same as HPIM (above) and with the same

tooling requirements. MicroPIM differs in

its ability to output highly-configured, complex-shaped ceramic parts as small as 0.05 Grams.

Learn more…

*Quantities are approximate. Many factors determine the appropriate manufacturing process.

People Making it Happen

Ceramco is the very best at what it does because of the people that work here. They

engineer and manufacture the stock ceramic

fasteners and OEM ceramic parts we deliver to our customers. Without them Ceramco is

just a building full of equipment, which is why they are so important to us. When you do

business with Ceramco you and your order, regardless of its size, will be treated with the

same respect and concern.

Ready to Make it Happen for You

Do you need a quotation on your print for a OEM ceramic part?

Contact Ceramco. You'll be greeted by a

courteous customer service specialist ready to provide immediate, personal assistance.

Ceramco specializes in manufacturing OEM ceramic parts with complex geometries, matching

the appropriate forming process to your order's specifications and quantity.