NEWS RELEASE

For Immediate Release on: July 19, 2023

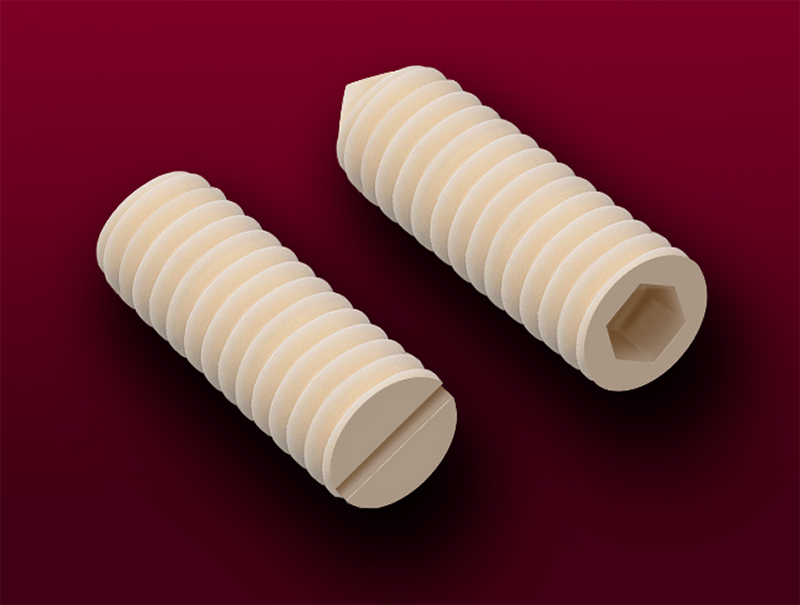

Solid Ceramic Set Screws

When Just Any ‘ol Set Screw Won’t Do…

A service temperature of 1650°C, non-magnetic, wear resistant, non-corrosive, non-conductive and biocompatible. It’s not just any ’ol set screw. It is a solid ceramic fastener from Ceramco, Inc., one of many from the growing family of stock ceramic fasteners, in-stock and available online and for immediate delivery.

A service temperature of 1650°C, non-magnetic, wear resistant, non-corrosive, non-conductive and biocompatible. It’s not just any ’ol set screw. It is a solid ceramic fastener from Ceramco, Inc., one of many from the growing family of stock ceramic fasteners, in-stock and available online and for immediate delivery.

Ceramco’s solid ceramic set screws are available in slotted and socket head, with either cone or flat points, both metric and U.S. inch, in full size range. Material compositions include alumina, zirconia and ZTA (zirconia toughened alumina).

Our set screws are 100% molded (no harsh machining) using our near-net shaping process, then fired to full density. Our New Hampshire, USA manufacturing facility is ISO 9001:2015 certified and ITAR registered.

Solid ceramic set screws from Ceramco are the solution for applications in which metal alloy or plastic fasteners fail or simply do not possess the properties demanded by the environment in which they must exist, including:

Order Ceramco’s ceramic set screw online at ceramicfasteners.com, or call +1 (603) 447-2090 (M-F, 8:00 am - 4:30 pm, U.S. Eastern) for immediate assistance.

In 1990 Ceramco pioneered the manufacture of solid ceramic fasteners as an outgrowth of its primary business: OEM ceramic components. Everything is manufactured under the watchful eyes and guidance of the same highly trained, expert engineers in Conway, New Hampshire, USA.

###